What Wire to Use to Make a Hanging Mobile and Where to Buy It

I get an email once in a while asking what kind of wire I suggest to use to make a hanging mobile and where to buy it. I just got one again and I figured I’ll just turn it into a post on my blog here.

Most of the time I use galvanized wire for my smaller mobiles which you can get at most hardware stores. It usually comes in a roll (see image below), usually 100 feet long and costs around $6 a roll. Two tips: if you can’t find it in the regular hardware section: sometimes hardware stores have wire in the dropped ceiling section and I’ve also seen wire sold in the household section as clothing line. Any place that has fencing supplies can be a good source too. If you can’t find them in any stores near you, you can get them online at a place like McMaster-Carr.

Wire comes in different gauges, the smaller the gauge number the thicker the wire. 18 gauge is very easy to bend and works fine if you’re attaching lightweight things to it like paper shapes. 16 gauge is sort of in the middle, and 14 gauge works good for a little heavier attachments (I use mostly 14 and 16 gauge for my two to three feet sized mobiles where the shapes are made of sheet metal).

If you’re planning on a mobile that’s a little bigger and a little heavier, you will have to get 12 or even 9 gauge wire, but when you go to that thickness it’s becoming increasingly hard to bend. Especially if you start using solid metal rods (rounds), you’ll need to figure out how to bend it in ways other than just with your hands and a pair of pliers. There’s a variety of rod and pipe bending tools that can be applied to certain aspects of making mobiles (if you’re willing to spend the money for one). Di-Acro benders are quality tools in the higher price range (The Art of Bending PDF by Di-Acro can be a useful resource). Or take a look at these instructions on how to make a hook bender, and there are videos on YouTube that show how to make your own rod bending tool.

If you’re planning on making a really large mobile, I recommend you use steel or aluminum rods (rounds) instead of wire, starting with 1/8 inch thick ones. You can get them at a smaller metal retailer such as Metal Supermarkets, or from a large commercial metal supplier like this one. If you’re going even bigger, using solid metal rounds makes the mobile too heavy, especially when using steel. Alexander Calder‘s giant mobile sculpture White Cascade, which measures 100 feet in height, was made with steel and weighs close to 10 tons (!). You want the mobile to move with the air currents. So for a large mobile (33 feet in height) that I made, I used hollow aluminum pipes and aluminum sheet. Despite its size, the mobile ended up weighing only about 100 pounds (45 kg). The 76 foot (23 meters) mobile by Alexander Calder at the National Gallery of Art in Washington, DC, is made with hollow honeycomb-type structures designed by Paul Matisse (grandson of Henri Matisse and son of Pierre Matisse) and covered with paper-thin aluminum, and aluminum and steel bars, with the stress points being strengthened with molybdenum. It weighs 930 pounds (422 kg).

There’s also a table on Wikipedia that shows various data including the gauge, diameter and more of the various wire gauges.

Wire that is already straight (not in a roll) is hard to find. Welding shops sell welding rods (electrodes). They’re straight and usually come in tubes and are usually 36 inches in length, and usually start at a diameter of 1/16″. You can get them in stainless steel or aluminum. Stainless steel is stronger and heavier, aluminum softer and more lightweight. Welding rods come in different alloys. The 1/8″ 4043 aluminum alloy can be bent by hand with pliers, and it’s easy to hammer out flat quickly if needed, but it’s stiff enough to support medium sized elements without flexing. You can also use 1/16″ and 3/32″ of the 4043 aluminum alloy for small mobiles.

You can find 12 gauge straight wire (not very easy to bend by hand) that’s 6 feet long in the dropped ceiling section at Home Depot. I just checked, I don’t think they sell it online but here’s what it looks like in the store (note it comes in a pack of 50):

You can also straighten wire with the help of a drill and a vice (41 sec video), or with the help of a drill and a wooden block (6:08 min video).

Calder also used piano wire (also known as music wire) from time to time. I found straight round music wire made by K&S Precision Metals at local hardware stores and hobby stores, such as HobbyTown. You can also buy it online directly from K&S Precision Metals. I would maybe try a wire diameter of 0.035″ and 0.047″. For larger mobiles, maybe try a diameter such as 0.055″. As you increase the diameter with music wire, it gets challenging, if not impossible, to bend it with regular pliers. Music wire is stronger, it doesn’t bend as easily. As a trade-off, it allows for thinner wire to be used to make a mobile, which makes for a more sophisticated look, depending on personal preferences.

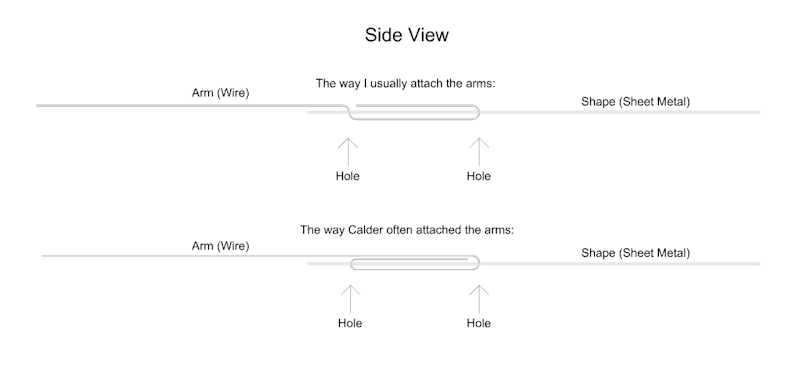

How to attach the wire (arm) to the sheet metal (shape):

Different methods of looping the wire into the two holes:

A photo of an original Calder mobile illustrating his looping technique (click on the photo for the large resolution image):

Calder seems to have preferred mechanical ways to attach parts to each other, most often with the help of loops and rivets. Most of his small to mid sized mobiles appear to be made with the two holes and a loop method. He only seems to have used welding on large mobiles and sculptures when really necessary.

In 1962, George Rickey wrote about Calder’s work: “His metalwork can be labored, clumsy and antiquated. Calder seems uninterested in expanding his command of cutting, bending and joining metal, except by farming out the big commissions to professionals – whereupon they lose his touch and the undeniable charm his technical primitivism sometimes imparts. He steadfastly refused to weld or solder or braze his joints; he has preferred to rivet or lace and crimp with wire (like a stapler), or to bolt.”

You can find a more detailed description on how to attach the arms to the shapes in my How-To Make a Mobile article on Houzz.

Additional resources for making mobiles:

- Blog post I wrote explaining some of the basics about the balance of a hanging mobile

- Blog post with mobile-making related questions that I’ve received via email and my answers

- An article I wrote for MAKE magazine on How to Make a Mobile Based on Calder’s Mobiles

- An article I wrote for Houzz: From the Artist: How to Make a Real Mobile – It’s All in the Balancing Points (there’s a number of questions and answers in the comment section of the article as well). The article is now also available in German

- A history of early mobiles that I’ve put together

- Some technical (“behind-the-scenes”) aspects of designing, making and installing a large custom mobile

- A definition of mobiles

- Q&A about Mobiles for a middle school student’s math class project

- See some of my mobiles if you’re looking for design ideas: handmade mobiles, large custom-made mobiles, 3D printed mobiles and kinetic sculptures

If there’s anything else I can help with, don’t hesitate to contact me.